Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By ren

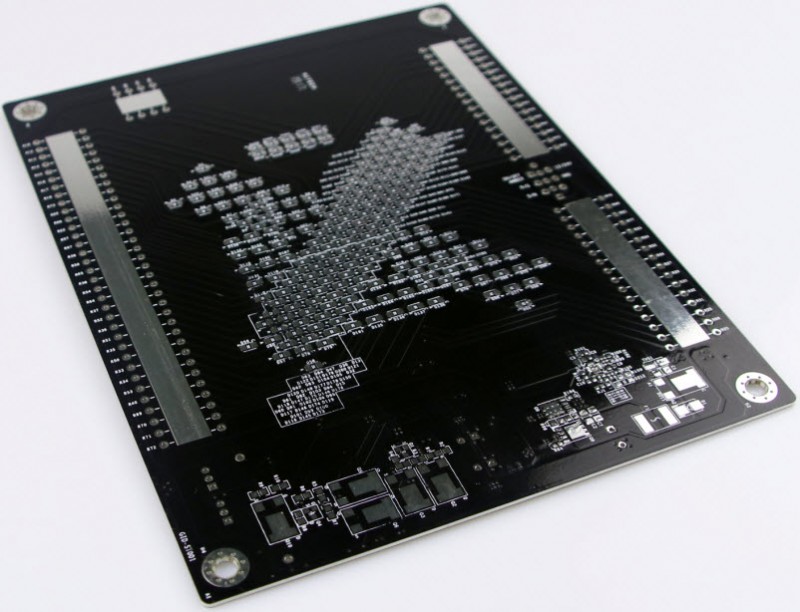

Do you know what is the difference between aluminum-based PCBs and other PCB s? Let's learn about aluminium PCBs and their applications!

The aluminum PCB is like any other PCB because it also has the same copper layer, welded mask, and screen printing on it.

But what is different here is the aluminium substrate. The substrate is of the metal base in an aluminium circuit board. Instead of using the substrate of plastic or fibreglass, it uses a metal substrate. And the base is made by using a combination of aluminium.

All agree that aluminum is more versatile than other PCBs. As the name includes the word base in it, so to explain it basically the base material consists of an aluminium core and the standard fr4.

Moreover, it includes a thermal resistance clad layer which makes sure to dissipate the heat in a very effective manner. This way the cooling of the system increases which makes it perfect for increasing the performance of the product.

This makes aluminum PCBs one of the best solutions for high tolerance applications and using high power applications.

Aluminum PCBs are mostly single-sided and can be double-sided as well. But manufacturing a multi-layer aluminium PCB is a hectic and difficult task.

Following is a list of products that lead to the formation and structure of aluminium PCB.

The first one to receive the etching was the circuit copper layer. The acid corrodes it, and then it forms a printed circuit board. This way it leads manufacturers to understand the assembly and connection of the device. In the comparison of the circuit copper layer with the fR-4, the aluminum substrate can carry a high power supply if the circuit copper layer has the same width and length.

This one is the core of aluminium substrate technology. It plays the function of bonding, insulation, and heat condition as well. In the power module structure, the aluminium substrate becomes the largest thermal barrier.

This means that the more the thermal resistance is the more beneficial it will be to spread the heat. The heat that was generated while operating the device. It will lead to lessening the operating temperature of the device.

Moreover gives the benefits of reducing the volume and extending the lifespan and lastly, it will also increase the power supply.

Lastly, the type of metal that will be used for the metal core substrate depends on several things. These include the thermal resistance, thermal conductivity, strength, hardness, weight, and even the surface state of the metal substrate.

Most of the technicians use the aluminium plate as it proves the best against cost and technical performance. Some of the available options that aluminium base PCB manufacturers can use are 6061, 1060, 5052, etc.

There are several advantages and benefits of aluminium PCB, let’s look out for that one by one:

One of the greatest benefits of aluminium is its non-toxicity. Yes, we are not talking about the toxicity of human nature. We are discussing the toxicity that can harm the environment.

Aluminium is non-toxic and recyclable. The manufacturing process of aluminium is very easy as it can be easily assembled which leads to the conservation of energy. This makes it healthy for the environment. So using aluminium can lead to a greener environment for the planet.

So printed circuit board manufacturers can have a very good point to make more aluminium PCBs as it leads to conserving our environment.

Basically, high temperatures can create a havoc situation leading to serious damage to electronic equipment. Therefore, there is one thing in the mind of manufacturers of electronics. That is they want a material that can dissipate that heat and not cause any harm to the product.

Here comes the role of aluminium. Aluminium can easily transfer the heat away from those components that were about to get damaged due to high temperatures.

It will also lead to saving the harmful effect on the printed circuit boards.

It’s in the nature of humans they prefer a product that is long-lasting and durable. Because durability can lead to cost-saving and makes the product works more efficiently.

The aluminium core works the best when it comes to durability. It provides strength and durability that other basic materials cannot give. I.e. ceramic or fibreglass etc.

It has been proved that aluminium core is subject to reducing any form of accidental breakage that can happen during everyday use.

With the added benefit of durability, aluminium is also very lightweight. What more will a product give? The one that gives strength, remains durable and even cost-effective. This makes aluminium an all-rounder.

Aluminium is a metal that is found in a variety of climates. This makes it easier to mine. Similarly, the refining process also gets a lot easier. The cost that comes from this process is very less compared to products that require lots of work to find and then there is also the cost of mining and refining. This makes the whole process of aluminium manufacturing cost-effective.

Investing in an aluminium core will be a beneficial fit if your product involves high temperatures. Otherwise, if you have in mind to make a flex circuit by using aluminium it might work, but the vibration stress will be difficult to endure. So, the best work that aluminium can give is when it is exposed to high temperatures.

Now as we have learned about the aluminium base PCB, let’s come to the main point. Who you will choose as a manufacturer?

We have a solution for you as we will advise a great company that specializes in the industry of PCB manufacturing. Let’s look out for things why you need to choose Europe PCB as your manufacturer for manufacturing aluminium base PCB.

As mentioned earlier, Europe PCB is a leading organization that specializes in PCBs. The things that were covered in the article before, like the requirement that should be seen while choosing a manufacturer.

All the requirements mentioned earlier are possessed by Europe PCB. Not only are those but the following are some of the things that will help you in choosing a good manufacturer. And why you should be opting for Europe PCB for your aluminium base PCB:

So what are you waiting for? Get your orders placed now and enjoy the best services.

Do you have any questions, or would you like to speak directly with a representative?