Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By ren

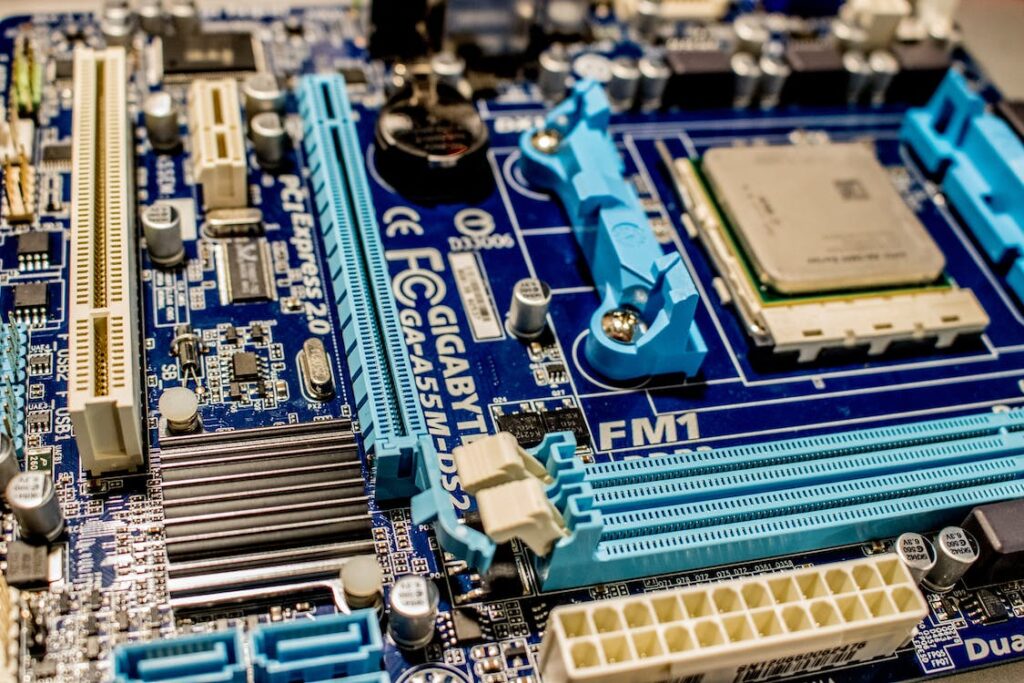

Custom PCB printing and assembly A-TECH has successfully met many high expectations and unique demands from our cooperative brands and is still seeking improvement and breakthroughs with our strong focus on sincerely delivering our brand values and brand goals, which has led to a steady increase in sales, wide recognition, word-of-mouth referrals and advocacy for products under our brand.

When developing bespoke PCBs, you need a schematic. A schematic is a diagram or plan outlining the connections and placement of all the parts that will make up your custom PCB Printing. To create a schematic file, utilize the right software.

1 Altium

2 KiCad

3 Quadcept

It's custom PCB optimized. For example, Quadcept's direct Bill of Materials export is quick and simple, and since the application is cloud-based, it can be accessed from almost anywhere.

In almost every electrical device we use daily, printed circuit boards are a necessary component that we cannot overlook for even a single second. But do you know how to choose a PCB that will precisely satisfy all of your needs? Or maybe you want to buy one but you're not sure whom to get it from? You need not worry at all.

This helpful article is here to help you with the six important considerations for custom PCB printing that you should keep in mind.

We hope that by the time you conclude this essay, you will have learned important facts about custom PCB printing.

A schematic must be created before you can build a bespoke printed circuit board. A schematic is a written description or design that shows how the parts that will be used in your custom PCB printing will eventually relate to one another and function well together. However, to create a schematic file, you must first make sure that the software application you select is appropriate for the task.

Many companies that create bespoke printed circuit boards favor the following:

Considering that it is well optimized in terms of custom printed circuit boards. For instance, Quadcept's direct Bill of Materials export is fast and easy, and because the program is cloud-based, you can use it almost anywhere.

It's important to keep in mind that there are more software tools available, including:

Some of the many different types of custom printed circuit board design software that are available to designers are heavily used due to their complete capability.

The layout of your board is the next consideration when printing bespoke printed circuit boards. You may use the same software tools discussed above to create the ideal layout. The layout of your custom PCB printing and assembly, in contrast to schematics, focuses entirely on assigning the components to the correct locations on the printed circuit board. It is also essential to display the traces that link each component to the layers of the printed circuit board.

As you may be aware, your custom-printed circuit board will get more intricate, difficult, and fashionable the more layers you decide to include. A printed circuit board's layout necessitates the technical know-how of seasoned experts with extensive experience in the area.

the custom printed circuit board design software, the assisted design system, or other competent techniques needed to transfer vital components toward the design of the finished printed circuit board. You must consider important elements like the following while planning the layout of your printed circuit board:

Designers may sometimes cite Gerber files while discussing the production of printed circuit boards. To create the layer structure of the printed circuit board, printed circuit board manufacturers provide Gerber files, which are computer-aided design files. A Gerber file, in essence, is a representation of the printed circuit board that shows each layer as it would be seen throughout the circuit design. They serve as representations of copper layer pictures, legend, solder masks, and route data that make it easier to understand how the circuit board must be constructed.

After the layout, PCB makers utilize Gerber files. These services are provided by several printed circuit board manufacturing companies, EuropePCB being one of them.

Your preferred printed circuit board manufacturer will be able to produce the circuit board as soon as you provide them with your Gerber files. Your printed circuit board serves as the foundation for increased production. You may easily add components to your PCB printing board by using Gerber files.

No of your production philosophy, you must think carefully about the materials you'll use. There are several components utilized in the production of Custom PCB printing and assembly. A few of them are led-emitting diodes (LEDs), which only let electricity travel in one way. Resistors are yet another essential component of printed circuit boards.

To reduce its cost, resistors accomplish work by regulating or managing the current. The batteries, transistors, switches, diodes, and inductors are other components. These are PCB design resources. When putting together paperwork, you may either go ahead and ask your PCBA manufacturer to place the order for you if you find it difficult to do so or if you already have the suppliers chosen, you can do it on your own.

When choosing components, you should bear in mind a variety of factors, including the component type number, optimal parts, packaging, lead time, and minimum order quantity. For instance, if you were considering buying fewer components than you needed, you would need to verify your minimum purchase quantity to ensure that all of the items you've chosen are available. Additionally, you should be aware that certain components may take 8 to 16 weeks to reach you in terms of lead time.

The whole cost of producing a printed circuit board, particularly for custom PCB printing, must be taken into account by a printed circuit board design engineer. Custom printed circuit board designers who are just starting sometimes overlook the expenses related to producing them

Most designers fail to account for factors like tooling costs, the distance between board components, and printed circuit board size, which might influence the price of producing bespoke printed circuit boards. But to make sure your custom printed circuit board is cost-effective, you need to consider several factors, including the price of tooling, the materials you'll employ, and the number of layers.

Small PCBs may lower manufacturing costs. Furthermore, choosing a PCB with basic shapes rather than more complex ones could be necessary. Nevertheless, you have the option to utilize inexpensively, some of which may take some importing, supplies rather than those that are easily accessible.

When it comes to Custom PCB printing and assembly, several elements are involved. Their weights, profiles, and board components are a few of them. The thickness of the printed circuit board is one of the most crucial things to take into account, however. But why, I hear you wonder.

The resistivity and conductivity of the PCB must be considered while designing it to meet its specifications. Thickness affects your PCB's functioning. There are many depth levels available, including standard, standard Fr-4, standard core, and standard two-layer thicknesses.

Read more: Everything You Need To Know About Flex PCB Manufacturer

At EuropePCB, we have expertise in producing customized PCBs. You don't want to delay on this topic any longer, as we at EuropePCB are right behind you. Our purpose is to guarantee that you not only obtain the appropriate vendor but also get the finest from what they must give you. All you need to do is give us a call, and we'll take care of the rest. Please get in touch with us as soon as possible to learn how to get items created using cutting-edge technology.

Prev: Multilayer PCB

Next: Not Next

Do you have any questions, or would you like to speak directly with a representative?