Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By ren

In other words, how does the PCB prototype board work? A PCB prototype board has several outlets and a grid for wiring components. This sort of board is the most fundamental form of the printed circuit board. These prototype boards allow the designer to decrease the number of solder connections and wires required to connect various circuit components.

The testing and prototyping of your schematic design is a vital step in any production process. Having a PCB board prototype will help you to identify design issues and fix them at this stage.

Before sending your product to the manufacturer, you must ensure that all problems and design defects have been eliminated. The last thing you want on your hands is thousands of defective items.

Creating a prototype of your circuit board layout provides another proof of concept. This is helpful for both establishing your intellectual property and showing your goods to prospective investors and customers.

But what is a PCB board prototype? This article will explain prototype printed circuit boards, their purposes, and the construction requirements connected with them.

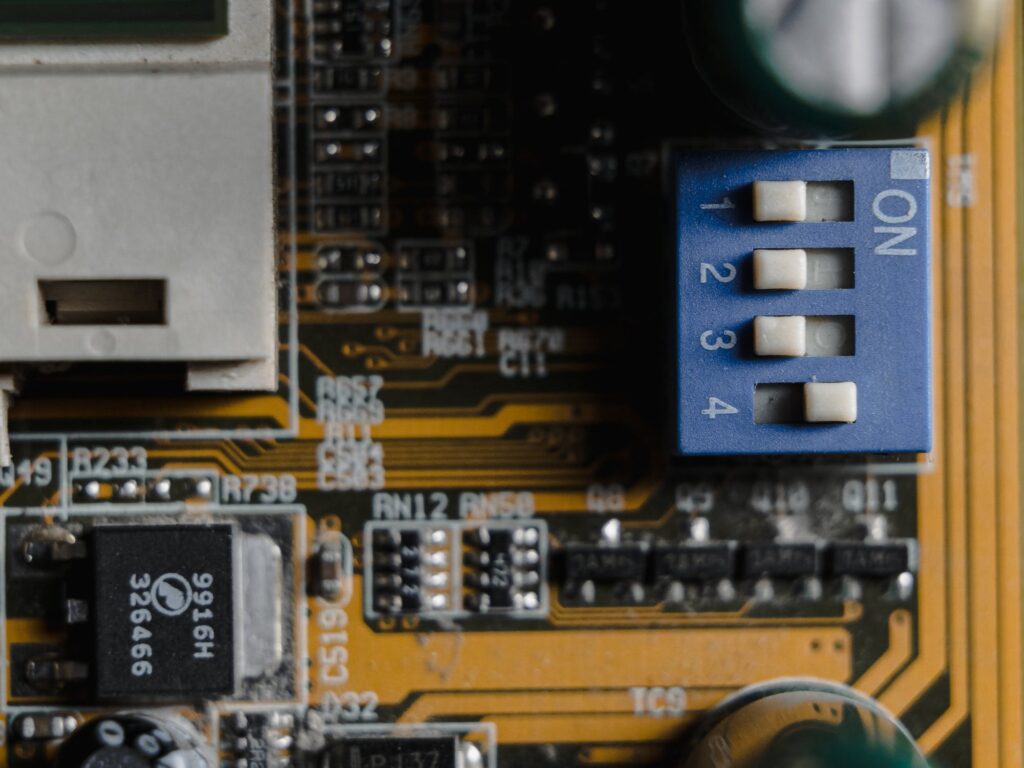

How does the PCB prototype board work? Multiple kinds of circuit boards exist. Copper rails link components on most single-sided PCBs. Double-sided and multi-layered PCBs exist.

Multiple components comprise a printed circuit board. FR4, copper, solder mask, and silkscreen are included.

FR stands for "flame retardant." FR4 is a laminate of glass-reinforced epoxy resin. This is the primary component of the circuit board, and it provides it with its stiffness.

The board is laminated with copper. This method requires heat and glue. The amount of copper plates used determines whether the board is a single-layer, double-layer, or multi-layer PCB.

To isolate the copper traces, the solder mask layer is present. This avoids solder jumps and maintains copper's isolation from other metals.

Silkscreen is the last layer of a printed circuit prototyping board. This helps assemble PCBs by printing letters and numbers. You can use any type of colour.

Through-hole technology involves inserting leads into holes on one side of a circuit board. Afterwards, they are soldered to the opposite side's copper layer. Soldering takes place directly on the circuit board when using surface-mounted technology. There is no need for leads. The benefit of surface mounting technology over through-hole boards is the possibility to design smaller PCBs capable of executing more complex operations.

Before you can construct a PCB prototype, you must have the necessary paperwork in place. Focus on generating documentation that is comprehensible and straightforward to verify that your design is accurate. Never treat your PCB manufacturing documentation as an afterthought.

The documentation on your PCB should give some background. This is especially important when designing novel or exclusive technology. Follow these steps to guarantee that your PCB manufacturing documentation is accurate and to make the process as simple as possible for yourself:

how does the PCB prototype board work What is PCB Rapid Prototyping then? Printed circuit board assembly. Specifically, PCB Rapid Prototyping. Printed circuit board assembly. Specifically, PCB Rapid Prototyping. 3D PCB Printing manufactures the PCB and performs the Printed Circuit Board Assembly (PCBA, an acronym for printed circuit board assembly.

Now that your printed circuit board is accessible, you may fill it with the necessary electronic components. You may be tempted to physically solder this yourself. PCB Rapid Prototyping may be a viable alternative when the number of panels is fewer than five or, in the worst-case scenario, 10; anything above that number may not be a smart idea. 3D PCB Printing produces both the printed circuit board and the printed circuit board assembly.

With the coronavirus epidemic and the issues it has brought to the world of business and commerce, it is advantageous to be able to produce your prototype PCB board in the United States.

Using Imagineering for your prototype and production will result in shorter turnaround times and reduced costs owing to the absence of tariffs. Contact us immediately for a price quotation and to discuss your prototype and PCB fabrication requirements.

Before purchasing a complete production run of a new PCB design, we suggest that you develop a prototype. Our prototype PCB service is quick and user-friendly, allowing you to test your board without delay or difficulty. PCB prototyping allows you to perform the following:

how does the PCB prototype board work? Before beginning the PCB prototype process, you should ensure that prototyping meets your demands. Many projects benefit from it, but not all. You'll need project details to build a prototype.

Read more: Everything that you need to learn regarding printed circuit board annular rings

In conclusion, while seeking professionally created prototyping printed circuit boards, you must supply comprehensive information. Errors on the website may be indicative of flaws in the prototype. This might result in a more time-consuming and costly testing procedure.

Do you have any questions, or would you like to speak directly with a representative?